Featured Post

- Get link

- X

- Other Apps

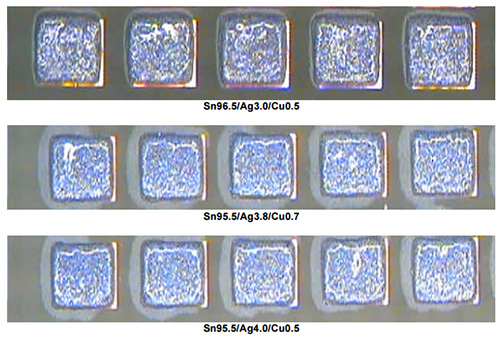

18+ Tin Silver Solder Melting Point PNG. In the chart below, you will find the melt and flow points. Solder is melted in order to adhere to and connect the pieces after cooling, which requires that an alloy suitable for use as solder have a lower melting point than the pieces being joined.

Silver solder is the king of pipe joints, but the higher melting tempreature (430 degrees to over 1300 degrees f) make it rather prohibitive to use with electronics.

The melting point of any material is defined as the temperature at which the solid becomes a liquid. Sn, ag, cu, or other metals. Easy to use and filleting ability. When you melt it, unroll 6 inches (15 cm) from the spool to keep your hand a safe distance away from the heat.

Comments

Post a Comment